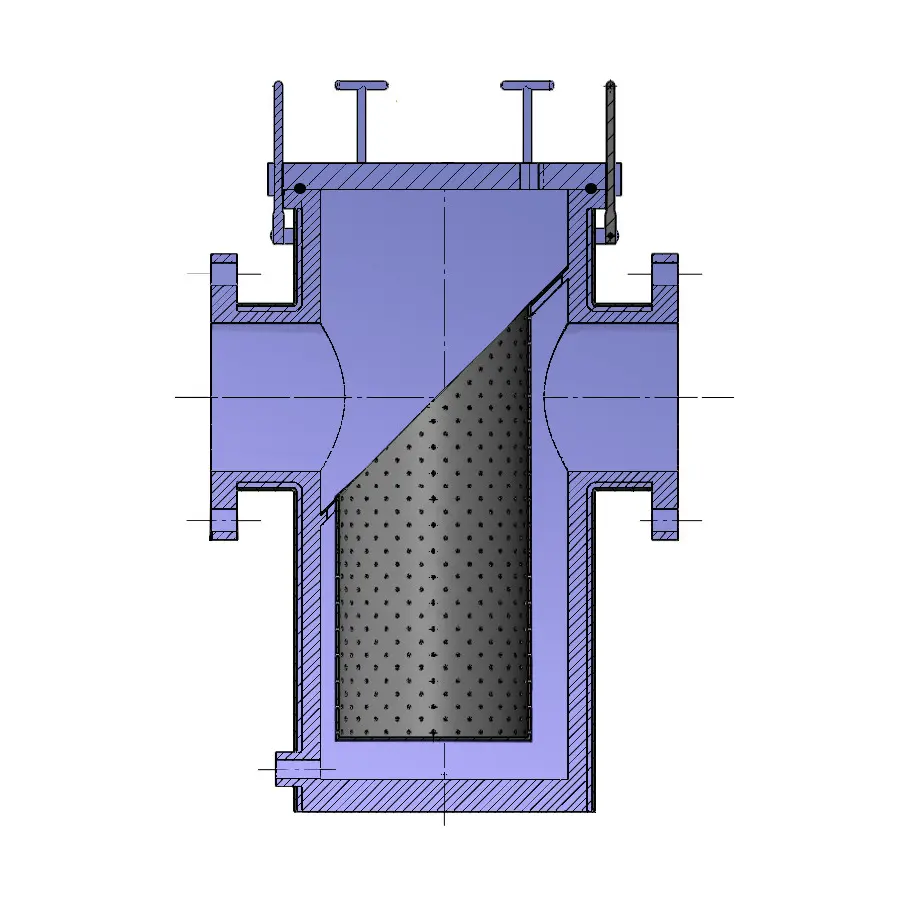

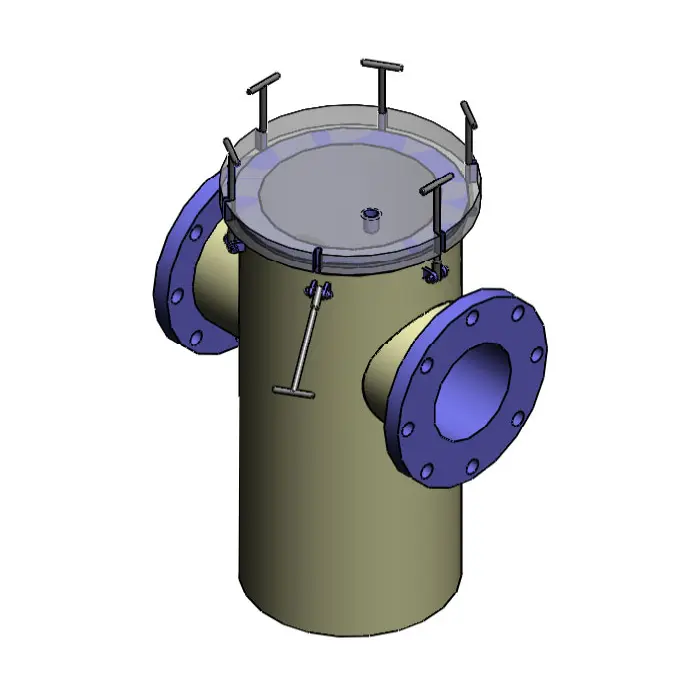

The SW Series is our most popular basket strainer for standard aquatic applications. The SW hair and lint strainer design has been refined over its 30+ years of production; it offers maximum performance, is user friendly and is the premier choice for many aquatic applications.

The SW is available in strainer sizes up to 24” and can be configured with in-line, offset, angled offset, or boot bodies. Not sure what you need? Call 888-551-0511 to speak to us immediately or contact us.

All of our strainers are available in duplex configuration, which includes the option is to purchase a duplex assembly minus the isolation valves. See our Duplex Strainers for more information.

Our most popular strainer for aquatic applications and some light duty industrial environments. Available in PVC/FRP & stainless steel.

Visit our Strainer Basket Detail page to see what strainer type works best for your application.

- Composite construction offers corrosion resistance of PVC and the mechanical strength of fiberglass.

- Molded FRP Body contoured for minimal form drag.

- Engineered for very low-pressure drops making it an excellent choice for pump suction applications.

- Best in class hardware and accessories.

- Customizable dimensions and features.

Acrylic Lid

- Clear acrylic lid features almost crystal clarity and weather-ability. Lid thickness depends on size of strainer. 10” and below have 1” thick lids. 12” and above have thicker lids.

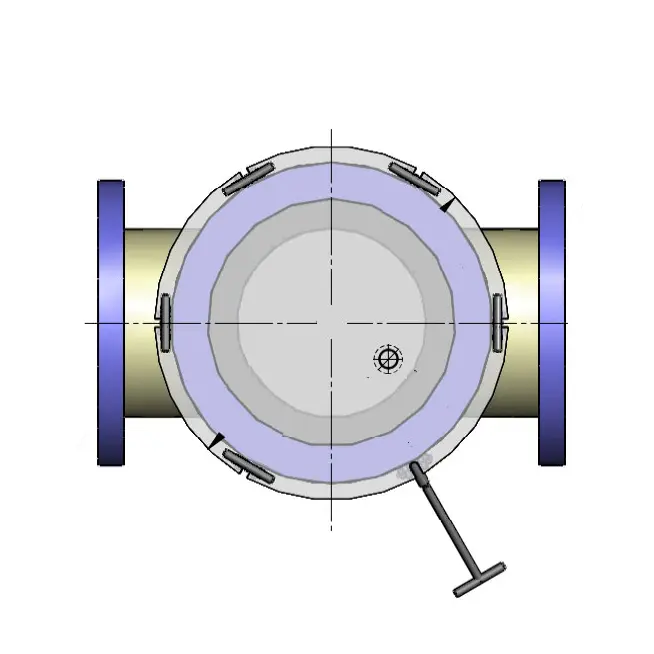

Flange Connection

- All strainers are supplied with loose rig flanges. PVC strainers utilize SCH 80 flanges produced from PVC type 1 and conform to ANSI B16.5, Class 150- up to 12” in size. Fabricated flanges utilizing PVC and FRP are provided for 14” and larger.

Flow Rate

- Sized for typical commercial aquatic flow velocities in respective strainer inlet pipe size.

Lid Attachment Assembly

- Machined from solid 316 SS bar and should outlast the strainer. Number of T-handles depends on size of strainer, e.g., 10” and below has 6 T-Handles.

Materials

- PVC/FRP or stainless steel

Standards

- AWSD1.1 AWSD1.3 ASME B31.4 ASME B31.9

Strainer Identification

- All strainers are given labels with a serial number for future reference. Complete records are kept at the factory. In the event an end user needs assistance, parts or replacement, Fluidtrol is able to identify the exact strainer. Even special circumstances of each individual unit can be filed.

- pdf FRP Data Sheet

- doc FRP Specification (docx)

- pdf SS304 Data Sheet

- pdf FRP Offset Strainer Data Sheet

- pdf Aquatic Duplex

- pdf Basket and Perforation Guide

- pdf Operation Manual

- pdf Acrylic Cover ID

- pdf Part Number Code