Basket strainers for commercial aquatic facilities, including aquariums, municipal pools, and zoos, are important parts of the suction sides of the pool recirculation systems used in those installations.

Selecting the right aquatic basket strainer when building a new facility or replacing existing equipment are important choices that should be based in a solid understanding of how aquatic basket strainers work and the options available. To aid in this decision-making process, we’ve outlined the anatomy of a commercial aquatic basket strainer.

In the past, aquatic basket strainer housings were made out of cast iron. Today’s strainer housings are larger and are made from either stainless steel or composite laminate.

We prefer to use PVC and fiberglass reinforced plastic (FRP) because both minimize the pressure drop in the line caused by large pipe diameter ratios. Combined, they also produce durable basket strainers that do not corrode, dent, rust, or conduct electricity and that weigh significantly less than equivalent stainless steel basket strainers while being just as strong.

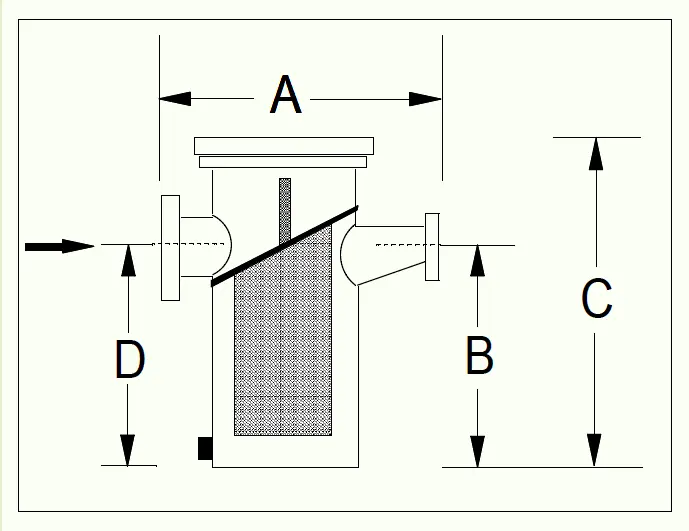

Composite basket strainers are made of a number of constituent parts: the lid, gasket, lid attachment assembly, strainer basket, flange connection, strainer identification, and drain plug standard.

Here is a diagram showing how these parts are arranged in an aquatic basket strainer. Each of these components is discussed in detail below.

Most composite hair and lint strainers feature a clear acrylic lid. Acrylic has outstanding weather-ability and will endure years of exposure to the elements. In addition, the choice of a transparent acrylic gives inspectors and facility managers the ability to monitor the status of the strainer basket in question without having to remove the lid.

For strainers with larger diameter bodies, acrylic lids can sometimes be too elastic, resulting in distortion over time as well as leaks. That’s why all of our aquatic basket strainers with larger diameters come equipped with lids made out of thicker sheet materials, which prevents this type of degradation. We also perform finite elemental analysis testing on our lids to optimize vent locations and other features of the acrylic cover.

Our acrylic cover diameters are dependent on housing size, which is determined by the strainer inlet flange size. Therefore, a 6”x 6” strainer would require the same acrylic cover as a 6”x 4” reducing strainer. Also, design changes over the years may impact lid dimensions and other features. If you have a Fluidtrol strainer and are looking for a replacement part, make sure you check out our Acrylic Cover ID Sheet.

Aquatic strainers require gaskets made out of various materials — most of which are compatible with pool water. The gasket system works with the lid attachment hardware to provide a quick-and-easy, low-pressure seal for the pump suction pool water.

For decades, gaskets for Fluidtrol aquatic basket strainers were ¼” thick and 1–2” wide and were considered flat gaskets. Today, our strainers are made with stock ¼” EPDM O-rings that can be found at gasket suppliers. If you prefer to go direct for your replacement parts, we also stock these O-rings.

Aquatic basket strainer lids can be attached using a variety of methods.

We prefer a tee handle assembly, which tightly secures strainer lids so they can withstand inevitable pressure surges. Machined from solid 304 SS bar stock, our tee-handle assemblies are much more resilient than the alternatives and will likely outlast the strainers they are attached to.

Strainer baskets can be made out of variety of metals with stainless steel being the most common for aquatic applications. Where corrosion is of primary concern, Fluidtrol also offers thermoplastic baskets as well as strainer baskets featuring high-alloy construction.

Depending on the size of the stainless steel strainer in question, we use either 18-, 16- or 14-gauge stainless to manufacture our extra-heavy-duty baskets. Our basket flanges are laser cut from 12-gauge stainless standard, making this potentially weak point super strong.

For our industrial FRP strainers, the environmental conditions and fluid stream dictate the best choice and Fluidtrol has expertise in them all.

Our composite strainers utilize SCH 80 flanges produced from PVC Type 1, Cell Classification 12454-B, that conform to ANSI B16.5, Class 150. Van-Stone-type flanges are supplied up to 12” size and are available for larger sized strainers as well. Flange ring rotation does help with bolt insertion in tight spaces as well as make hole alignment less critical in some cases.

Including a strainer serial number supports manufacturing quality control and facilitates service throughout the life of the strainer.

Each of Fluidtrol’s aquatic basket strainers comes with a label featuring a unique serial number, which is recorded at the factory. These numbers can be referenced to expedite service or replacement part orders throughout the life of the strainer. If a serial-number tag is ever damaged or removed, we offer free replacement of these labels for the life of the strainer.

A drain is standard and is important especially during winterization. Also, it is routinely used to drain a portion of the strainer housing contents while servicing the basket.

Pressure taps can be supplied on a strainer inlet and/or outlet arms. For more about the technical importance and ramifications of measuring pressure drop within basket strainer systems, please contact Fluidtrol for reports that detail this.

When selecting an aquatic basket strainer, make sure to take a closer look at the constituent parts that have gone into making the strainers you have under consideration.

A basket strainer is a carefully engineered assembly and a design flaw or poor materials selection for a single component can lead to costly system malfunctions or expensive, inconvenient, and unnecessary frequent maintenance.

Ideally, you should select a basket strainer that is quality through and through and that will stand up to its environment for decades. Our SW, RSW, ESW series strainers are built to do just that. Take a look. And if you have questions or don’t see quite what you need, give us a call at 888-551-9115.

We regularly customize our aquatic basket strainers to meet specific customer needs.