It is a technology that has already transformed our world. The oil-rich nations of the Persian Gulf already have giant desalination plants that supply their kingdoms and emirates with vast quantities of drinking-water straight from the ocean. It makes perfect sense that oil-rich desert states are the first major birthplaces for the desalinization industry: for now, the energy consumption that goes into most of today’s desalination plants is simply too costly for most countries to entertain on a large scale. But all that is already changing. As desertification becomes ever more present across the planet, the need for cheaper desalination technology is becoming increasingly apparent. Read more...

In today’s highly competitive global steel market, American steel mill owners and operators are charged with maintaining unprecedented levels of productivity in their operations. Faced with an overwhelming number of highly qualified international competitors, American steel mills have adapted various means and strategies of optimizing their milling process, including relying ever more heavily on automated equipment. Read more...

If you ever want to discover just how corrosive saltwater can get, try this little experiment for yourself: fill up a sand pail with water from the beach, dunk a standard metal dinner-fork in the pail, and then wait overnight. In the morning, you’re more than liable to see a fine coating of rust up and down the fork’s surface. In short, it doesn’t take an advanced degree in chemical engineering to realize that saltwater is a whole lot more corrosive than freshwater. Read more...

However often pundits like to talk about the growth of the solar and wind renewable energy sectors, when it comes right down to it, America is very much still dependent on coal.

Statistically speaking, coal accounted for roughly 42% of our nation’s power supply in 2011, with that figure dipping only slightly in the subsequent years. In states with concentrated industrial bases like Texas, Alabama, Georgia, Ohio, Pennsylvania, Indiana, Illinois, and Michigan, coal plays an even greater role in terms of keeping the lights on, the turbines running, and the smokestacks piping. Read more...

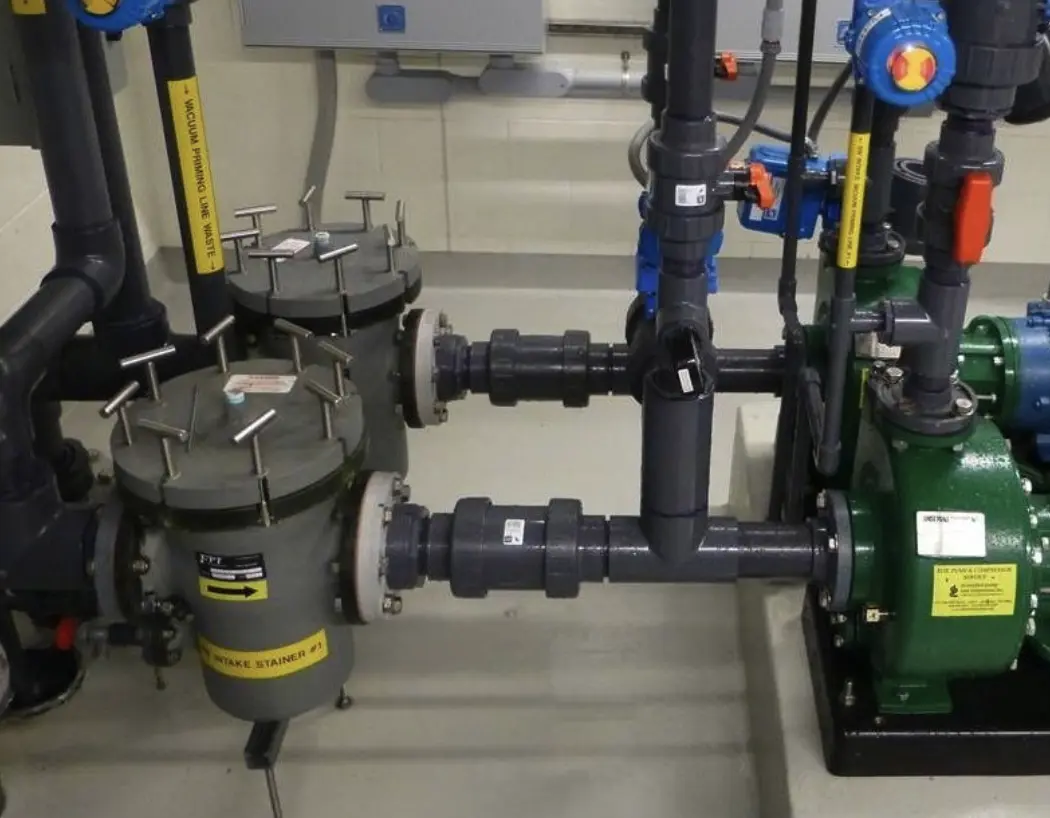

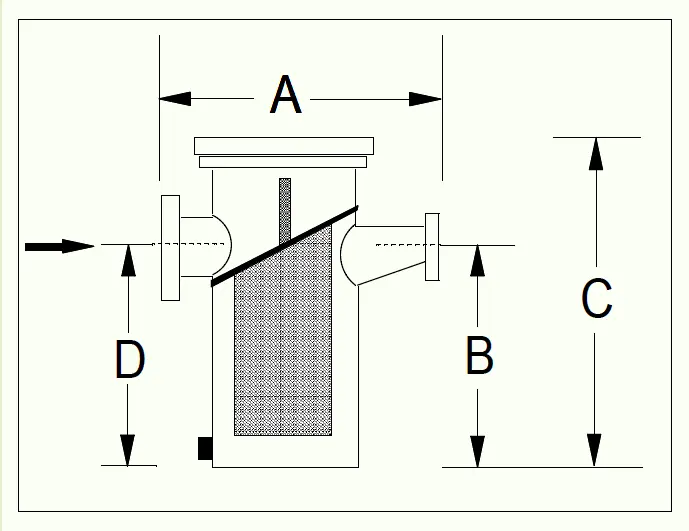

Hair and lint strainers used in commercial pools are a very important part of the filtration system of the pool. This simple devise is used to remove large objects, like jewelry, adhesive bandages, hair, lint and almost anything that can come out of a bathing suit pocket or even things that are thrown in the pool. The damaging materials aren’t always from the swimmers; leaves, stems, and rocks often make their way into pools. After a few years of cleaning filter baskets, it’s hard to be surprised at what you find. Removing these objects from the line will protect the pump and downstream filtration equipment. Read more...

Basket strainers for commercial aquatic facilities, including aquariums, municipal pools, and zoos, are important parts of the suction sides of the pool recirculation systems used in those installations.

Selecting the right aquatic basket strainer when building a new facility or replacing existing equipment are important choices that should be based in a solid understanding of how aquatic basket strainers work and the options available. To aid in this decision-making process, we’ve outlined the anatomy of a commercial aquatic basket strainer. Read more...

Industrial basket strainers — which are used in heavy industrial applications such as mining operations, power generation facilities, and chemical and metal refineries — are subjected to some of the harshest working conditions.

The fluids that pass through industrial strainers are some of the most corrosive liquids out there, such as seawater, pickle solutions, scrubbers, and various chemicals. This means they have to be built tough to resist their environments and remain operational. Read more...

If you’re using a wet scrubber for air pollution control, you know how they work: They capture flue gas particulate matter in liquid, dissolve it, and then separate it from the capturing liquid, recirculating treated liquid for future efforts.

This process inevitably involves pumps, which need to be protected from the abrasive, erosive particulate matter that wet scrubbers capture, transport, and separate. Industrial strainers are placed upstream from pumps in wet scrubber systems to protect them from particulate matter as well as unanticipated materials that might wreck machinery — such as wrenches, nuts, and bolts accidentally dropped during maintenance. Read more...