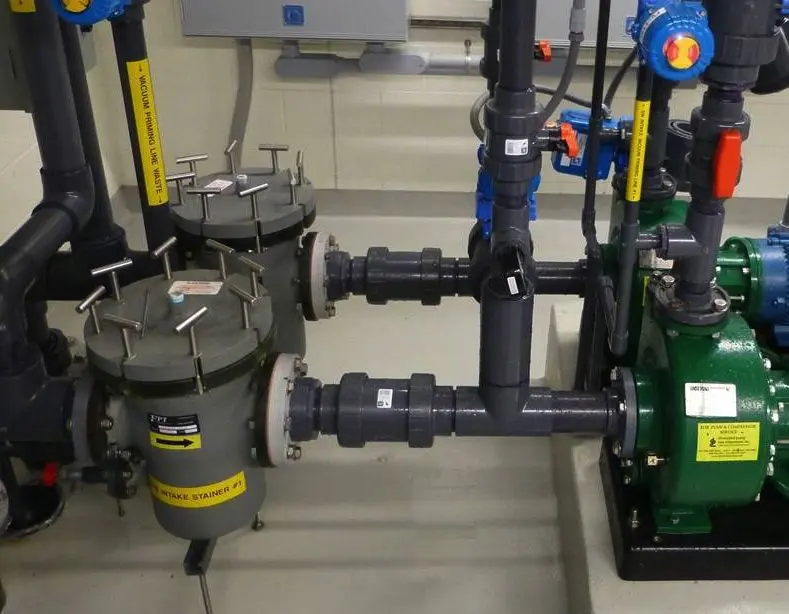

The FRP Series (Fiberglass Reinforced Plastic) is a state-of-the-art basket strainer system that is chemically tolerant of most industrial and process chemicals. Typical applications include corrosive chemicals inline pipe or as a pump strainer. These strainers can dramatically improve protection of corrosive system components such as pumps and heat exchangers.

Port configurations include the standard inline design, as well as offset, angled offset, and boot configurations if required. The FRP’s unique five-part construction delivers the finest in chemical, abrasion, and impact resistance:

- Two Chemical Barriers: Nominal thickness 10 mils of Nexus veil, resin to 10% reinforcement. (Layers 1 & 4)

- Anti-wicking barrier: 100 mil of chopped strand glass, 75% resin to 25% reinforcement. (Layer 2)

- Structural Layer: Filament wound continuous roving, wind angle 55 deg: 30% resin to 70% reinforcement. (Layer 3)

- Exterior Protection: Polyester resins gel coating. 10-mil thickness. (Layer 5)

All of our strainers are available in duplex configuration, which includes the option is to purchase a duplex assembly minus the isolation valves. See our Duplex Strainers for more information

Two chemical barriers and high impact resistance make this strainer ideal for larger saltwater and corrosive industrial applications.

Available in Various Vinyl Ester Resins.

- All inlets and outlets are of flanged construction as standard

- Includes bolted blind flanged tops and options include easy-off swing bolts or T-Handle hardware.

- Engineered to provide the lowest practical pressure loss.

Flange Connection

- All strainers are supplied with Flat Faced FRP Flanges and conform to ANSI B16.5, Class 150.

Flow Rate

- Designed for standard flow rates in respective line sizes.

Lid Attachment Assembly

- Bolted blind flange covers offer the highest pressure rating possible for these non-metallic housings. Options exist for easier lid removal with lower pressure rating.

Materials

- Vinyl Ester Resins, various glass and other reinforcements and various baskets.

Standards

- ASME Sec X , PS-1569

Strainer Identification

- All strainers are given labels with a serial number for future reference. Complete records are kept at the factory. In the event an end user needs assistance, parts or replacement, Fluidtrol is able to identify the exact strainer. Even special circumstances of each individual unit can be filed.

- pdf Data Sheet

- pdf Operation Manual

- pdf Part Number Codes

- pdf Specifications